Storage and handling of sheet materials

A worker was fatally injured after being struck by falling solar collectors for hot water systems, which were stacked on their edges. Other incidents have occurred involving sheet materials stacked on their edges falling due to inadequate support when being moved.

Sheet materials may include:

• glass sheets, windows or shower screens

• sheets of stone or marble (e.g. kitchen bench tops)

• plywood, MDF, chipboard, plasterboard, doors or other building products

• prefabricated frames and trusses

• reinforcing mesh and steel plate

• solar cells (e.g. photovoltaic cells and solar collectors for hot water systems).

Contributing factors

Workers or others in the immediate vicinity of stacked sheet materials are at risk of being crushed, trapped or cut by falling sheets of material. Workers may also sustain musculoskeletal injuries when they are required to manually balance stacks of sheets during sorting and handling.

The risk of severe or fatal injuries is high when materials, which have been stacked on their edges, are being handled or moved and the sheets are not adequately supported by suitable racking or transport frames.

Action required

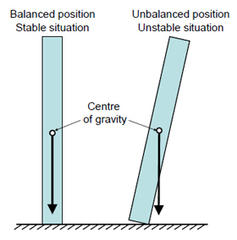

Where it is necessary to store materials on their edges, the stability of the stacked load must be accounted for in the design of the support system. An item is in a stable (balanced) position when it is restrained with the centre of gravity directly above the supporting edge. If the centre of gravity is inadvertently moved outside the supporting edge, the item will become unstable.

If sheet material of any kind is to be stored or handled, controls must be in place to safely support them. Stacking of sheet materials without an adequate restraint is potentially very dangerous.

An obligation holder, whose workplace includes areas where goods are stored on their edges, must implement controls to eliminate or minimise the risks of death or injury. This may be addressed by using a combination of:

• engineering controls, such as a rack or transport frame, to securely store, cradle, lift, transport and restrain the sheets

• safe systems of work (e.g. use of mechanical lifting equipment whenever possible, regimes for maintenance, inspection and testing of all racking and lifting equipment)

• adequate training and supervision of workers engaged in the work.

Where materials are stored in strapped bundles the risk of injury when the strapping is cut must also be assessed.

When strapped bundles are opened for the first time, purpose-designed support frames or temporary restraint should be provided to ensure the load does not become unstable.

Sheets of material of more than one type or size should never be stacked against walls or in areas without adequate support. Storage systems should separate sheets of different types and sizes to simplify the sorting task.

The support system needs to be designed for forces resulting from unbalanced loads.